Customized Linear Technology Solutions

At HSB Automation, everything revolves around customized solutions in linear technology – driven by passion and dedication. As experienced specialists, we support our customers from the initial idea all the way to the finished solution – all from a single source. Design, development, and manufacturing take place under one roof.

Whether it's about modifying an existing unit or developing a completely custom special solution – we implement what is technically feasible and economically viable.

For many years, we've been creating well-thought-out solutions that we proudly look back on with our customers. Below, you'll find an overview of our capabilities.

Got something else in mind? Get in touch – we can bring your custom solution to life.

Modified Standard Units

When standard isn’t quite enough: Our modified standard units are the perfect entry point into the world of customized solutions. Through targeted adjustments – technically sound and practically oriented – we tailor our proven standard units to your specific application.

Some practical examples:

- Linear units with temperature-resistant Valflon cover band

- Linear units with sealing air connection

- Stainless steel variants for demanding environments

- Cleanroom-compatible designs in various classes

- Explosion-proof designs based on ATEX requirements

Your advantage: Short implementation times, proven technology – and still customized.

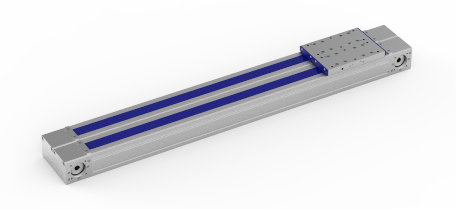

Manifold Linear Units

Compact, powerful, and versatile – the manifold linear units of the HSB-beta® series stand out with their exceptionally flat and wide design, while delivering impressive performance. All sizes can be configured into 2-, 3-, 4-, or 5-fold linear units, with a choice of toothed belt or spindle drive. The individual linear units are precisely bolted or bonded together, ensuring a stable, load-bearing, and perfectly aligned system

Learn more …

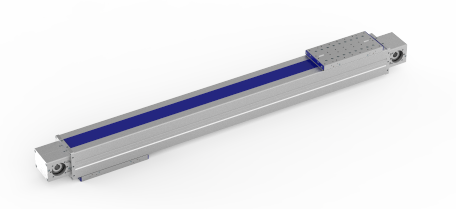

Right-Left- and Dual-Drive Linear Units

Our right-left linear units and dual-drive linear units offer maximum flexibility for applications requiring complex motion logic. They are ideal for handling, assembly, and positioning processes where movement must be either synchronized or independently controlled.

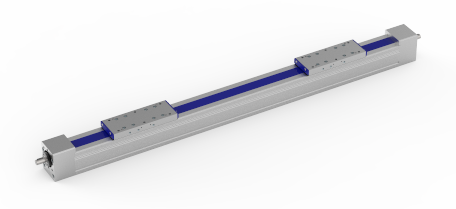

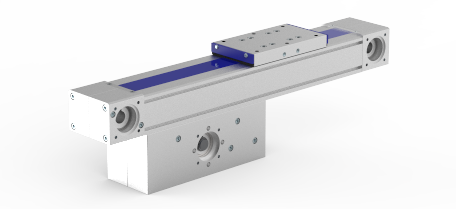

Double-Stroke Linear Units

When the required stroke length exceeds the available installation space, our double-stroke linear units offer the perfect solution. Thanks to their particularly compact design, two carriages, and actively driven profile, these units effectively double both the stroke length and travel speed – efficient, space-saving, and dynamic.

Depending on the version, the drive motor remains stationary or moves together with the profile – ensuring maximum flexibility in system planning and optimal adaptation to your application.

Learn more …

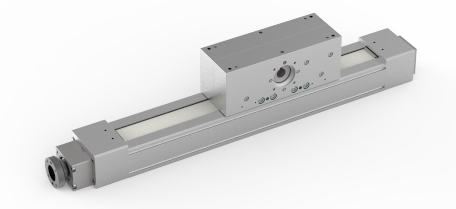

Rear-Mounted Omega Drive

When direct motor mounting to the bearing housing of a toothed belt unit is not feasible due to space constraints, the underside-mounted (side E) Omega drive offers an excellent alternative: powerful and space-efficient.

Learn more …

Rotary Feedthroughs

Precise rotary feedthroughs are available for various sizes of the HSB-beta®, HSB-gamma®, and HSB-sigma® series. These are particularly suited for use as vertical axes—anywhere grippers or tools need to rotate.

Learn more …

Portal Linear Units Made of Steel

For especially stable and load-bearing applications, we rely on our HSB-gamma® 300 and HSB-gamma® 400 portal linear units. They feature high-performance steel base profiles designed to reliably absorb and transfer forces and moments. The proven drive and guide system from our smaller HSB-gamma® units has been specifically reinforced to ensure precise and dependable operation—even under the heaviest loads.

Learn more …

Heavy-Duty Linear Tables

Where conventional linear tables reach their limits, our HSB-alpha® heavy-duty linear tables take over—the steel-strong solution for the most demanding applications.

Learn more …

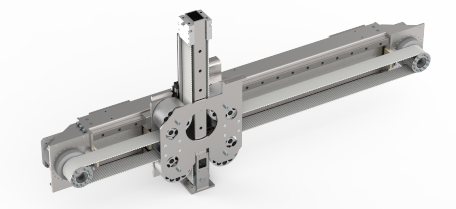

2-axis system with standing drives

In the case of highly-dynamic applications, it is always important to keep the moving mass as low as possible. We have been able to achieve this with our HSB-kappa® special unit.

Learn more …